Authors: Ali M.Al-Hawbani1,Marwan A. Al-Badani2, Ali M.Qaid3,KhaledM.Al-Selwi4 and Mohammed Alnuaimi5

1,2,5 Department of Geology and Environmental Sciences, Faculty of Applied Sciences, Thamar University, Yemen

3 Al-hajar (Qabitah) Community College-Lahj-Yemen

4 Department of Earth and Environmental Sciences, Faculty of Science, Sana’aUniversity, Yemen

I. INTRODUCTION

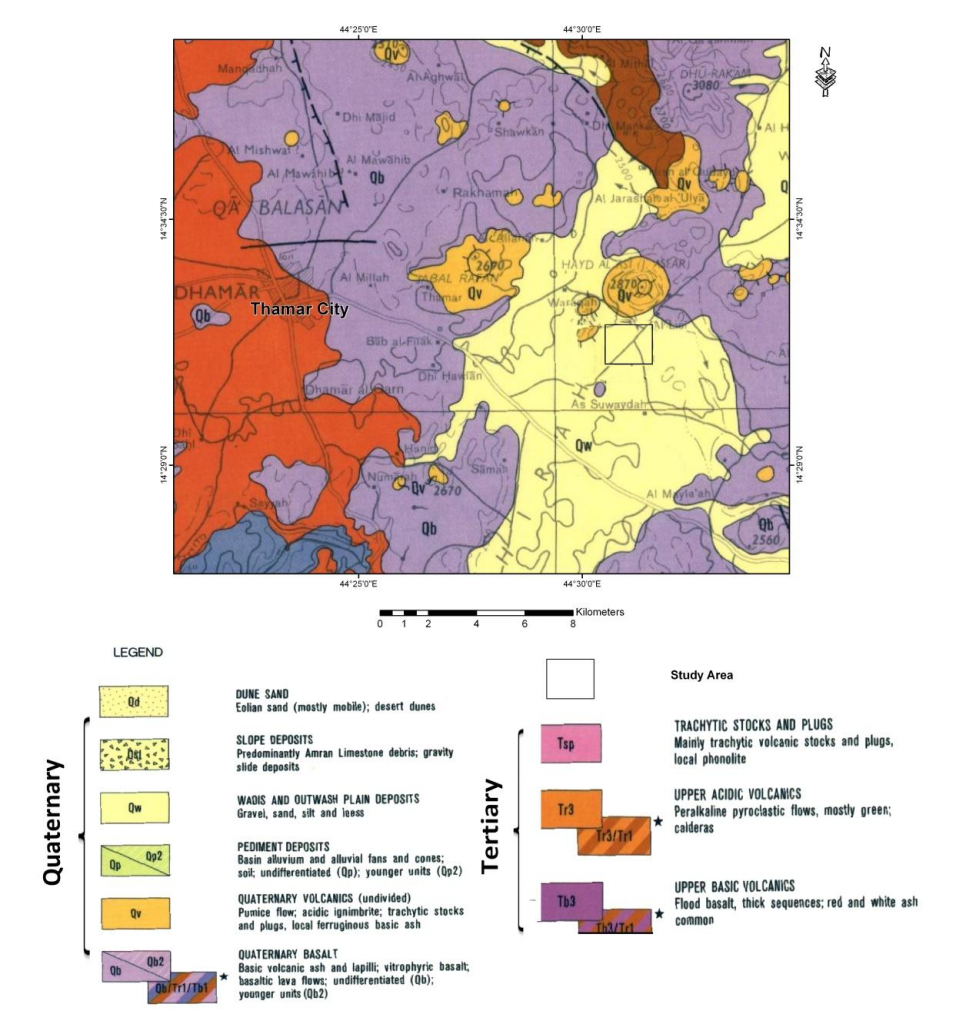

The Al-Lisi volcano is located about 15 km. east of Thamar City. They are bounded by latitudes 14° 24′- 14° 30′ N and the longitudes 44° 24′- 44° 32′ E. The study area is covered by Yemen Volcanic Group (basalt and rhyolites) and Quaternary Wadi deposit. The pumice rocks are outcrops in Thamar- Rada’a volcanic field.

Pumice is light-colored (white or grey), cellular almost rock made up of glass walled bubble casts. It may occur as coherent, massive blocks composed of highly vesicular glassy lava in either a flow or it may be more or less fragmented by violent eruption(Evans et al.,1999, Harben & Kuzvart, 1996, Wade et al., 2005, Presley, 2009, Pichavant et al.,2011 and Kikkawa, 2013). Pumice is a vesicular volcanic rock,typically has a chemical composition similar to rhyolite. The term vesicular refers to the presence of vesicles or irregularly shaped cavities, that produce a sponge-like or bubbly and very low density in volcanic rocks (Klug et al., 2002,Pattan et al., 2008, Manga, 2011 and Arce et al., 2015).

The physical properties of pumice are governed by the cellular structure of the matrix, these cells are independent to each other, which means that the level of sound and heat conductivity are both extremely low. The hardness of pumice is approximately 5.5-6 on the Moh’s scale (Geitgey, 1994,Founie, 2005, Presley,2009 and Al Sharie et al., 2015). Due to the microscopic size of the pores, which make up about 85% of the pumice grain volume, pumice is able to float on the surface of water (Harben & Kuzvart, 1996, Klug et al., 2002, Wade et al., 2005 and Presley, 2009).When the vesicles are interconnected the pumice is permeable and highly absorbent, and when they are isolated the rock is highly porous but very impermeable. This porosity, together with a large surface area and chemical inertness allow pumice to be used as absorbent (Pattan et al., 2008, Presley, 2009 andCrangle, 2011). Alsothe suitability of pumice for a particular end-use is dependent on their physical properties such as density, grain-size, grain-shape and friability.

The chemical composition, particularly SiO2 content is also important because a high SiO2 content will increase hardness and increase resistance to chemical attack(Robbins, 1984, Evans et al., 1999 and Presley, 2009). Pumice is used as aggregate in lightweight concrete, as landscaping aggregate, and as an abrasive in a variety of industrial(Geitgey, 1994, Crangle, 2011 andAl Sharie et al., 2015). It is used as abrasive and polishing to teeth and restore gleam. Hardness of the abrasive particle is profoundly important to the rate of polishing (Wilkins, 2009).The hardness, size and shape of particle are what make abrasive. Abrasive particle must be harder than the surface or material being polished, harder particles abrade faster(Hutching, 2002, Williams, 2005).

A number of factors contribute to pumice being widely used for polishing and cleaning applications in laboratories and consumerproducts – abundance, neutral in pH chemically benign hard enough to abrade yet soft enough not damage the surface but pumice’s characteristic friability is where it really shines meaning the pumice can be ground down to an ultrafine powder and still retain is abrasive quality(Wilkins, 2009, Pascarett-Grizon et al., 2013 and Sawai et al., 2015).

The gritty texture of pumice makes it ideal for polishing smooth surface. The outer layer of teeth, called the enamel, is the hardest substance in body, when the surface of enamel becomes scratched or pitted, plaque and bacteria have more places to hide and a rougher surface to cling to. When teeth are polished with pumice, it removes the plaque and bacteria before it affects the gums, and smooth the surface of teeth (Anusavice and Antonson,2003; Hutching, 2002, Madan et al., 2009 and Sawai et al., 2015). This study aims at examining volumetric, chemical and petrographic properties of the pumice rocks from Al-Lisi area, in comparison with the imported pumice material which is used as abrasion and polishing for teeth, as well as the possibility of using Al-Lisi pumice instead of the imported.

II. GEOLOGICAL SETTING

The geology of the studied area shows wide exposures of different types of basic and acidic volcanic rocks including pumice. The area is mainly composed of Tertiaryand Quaternary volcanic rock sequences (Fig.1). The studied pumice rocks belong to theThamar-Rada’a volcanic field.

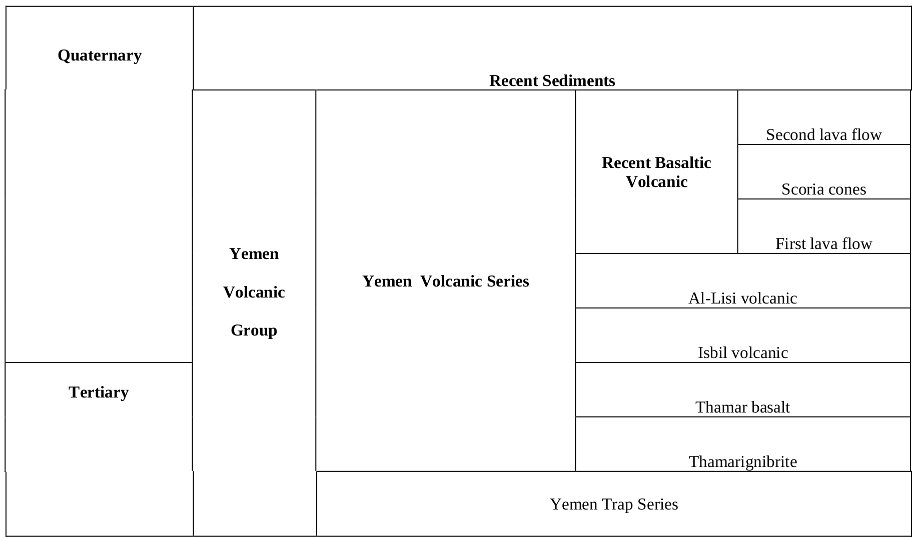

Stratigraphic evidence table (1)suggests that the sequence of volcanic events from the oldest (at the bottom) to the youngest (at the top) may summarize (Al-Sabri, 2009) as follows:

Table 1: Stratigraphic Column Of Thamar – Rada’a Field Sequence Of Volcanic Units

III. YEMEN VOLCANIC GROUP

The term “Yemen Volcanic Group” has crept into semi-formal use during 1990 – 1994 (Menzies et al., 1990., Menzies et al., 1992 and Al-Kadasi,1994), and appears initially to have been interchangeable with the term Yemen volcanics (Grolier and Overstreet, 1978).

Yemen Volcanic Group intermittently to include or exclude Pliocene or Holocene Volcanics(Mattash and Balogh, 1994).

The term is redefined for simplicity, to group together all the Paleocene- Quaternary Volcanic

Rocks of Yemen previously divided into an old “TrapSeries” and younger “Volcanic Series”(Beydoun et al., 1998). The Yemen Volcanic Group in the Thamar-Rada’a area are mainly consist of Yemen Volcanic Series with some outcrops of Yemen Trap Series table (1).

A. Yemen Trap Series

The Yemen Trap Series mainly outcrops in the northern and southern part of the study area. It is made up mostly of basaltic and rhyoliticrocks, most of the rhyolitic rocks are ignimbrite. In the upper part of the trap series the occurrence of central activity is suggested by some felsic lava domes, a few of which had precursory explosions terming “pumiceramparts”.

B. Yemen Volcanic Series

After the emplacement of the Yemen Trap Series, the Thamar-Rada’a area was affected by intensive vertical tectonic, with formation of horst and graben structural pattern. In this framework, central and fissural volcanic activity took place forming the Thamar-Rada’a volcanic field. This volcanic activity in many different phases has continued up to recent times(Chiesa et al. 1983) table (1).

C. Thamar Ignimbrite

The ignimbrite rocks are widespread in the western part of the studied area. They are composed of three different pyroclastic- flow units (ignimbrite a, b, c) reaching maximum thickness of 60 m. The lowest pyroclastic-flow (ignimbrite a), which might reaches up to 30m in thickness is a pumice flow formed of abundant pumice clasts and minor lithics embedded in ash matrix.

D. Thamar Basalt

It lies on the Thamar ignimbrites above an erosional surface with a local paleosoil. It is considered to be fissure basalts because they are not related to any known central volcano. The basaltic fissure activity followed the Thamar ignimbrite whose K/Ar ages are 5.7 Ma (Manetti et al.,1991). Basalt from the Thamar zone are black colored rocks, with grey, greenish shades compact, with porphyry texture, sometimes with aphanitic texture.

E. Isbil Volcanics

The Isbil volcano is located east of Thamar City. It is the prominent strato-volcano in the Thamar-Rada’a volcanic field. Its eastern part contains a collapsed caldera, the remainder part are deeply eroded. The caldera rim is not completely preserved. Post-caldera activity has produced an ash cone and some domical lava flows. The acidic lava flow consist mainly of rhyolites with ignimbritic and pyroclastic fall deposits.

F. Al-Lisi Volcanics

It is composed of lava flows and pyroclastic deposits. The lava flows occur as volcanic domes west of the Al-Lisi volcano and the autoclasticrhyolitic lava flows. They consist of black rhyolitic obsidian with vesicular, shiny and conchoidal fracture and laminar textures in same places. The pyroclastic deposits which cover about 15 km2 are located in the area around the Al-Lisi volcano as pumice and pumicitelayers.

G. Recent Basaltic Volcanic

The Quaternary volcanics are represented by central and fissure volcanism. The fissure volcanism is characterized by widespread basaltic lava flows and spatter cones, extensive basaltic obsidians, and pumice in the Thamar-Rada’a area. They are composed of three subunits:

(i) first lava flows,

(ii) scoria cones,

(iii) second lava flows.

IV. MATERIALS AND METHOD

The methods of this study are including the field work and the laboratory analyses. The field work was carried out including define the pumice rock, and collection of rock samples from different outcrops in the study area.Twenty nine representative rock samples collected from the select stratigraphic sections of pumice rocks. The laboratory analysis is including volumetric, chemical and petrographic studiesof the rock samples.

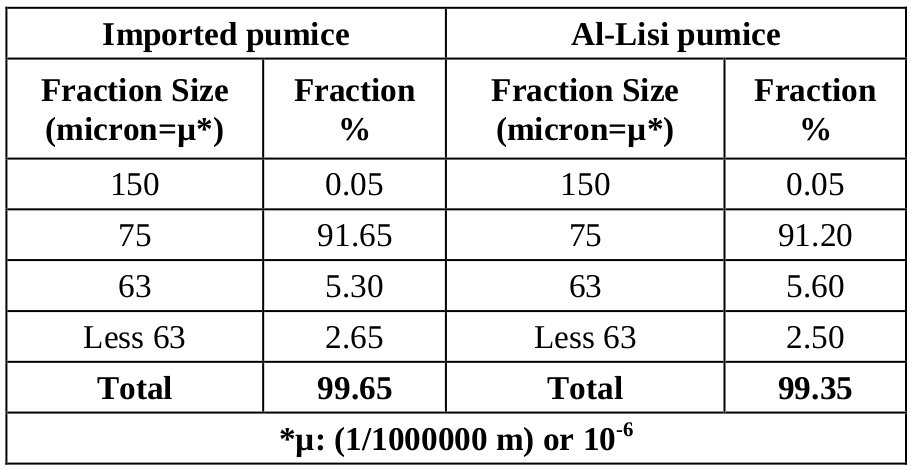

Volumetric analysis, one kg.of imported pumice was bought in order to carry out study and comparison with Al-Lisi pumice. We have taken 300 gm.to conduct the volumetric analysis through sieve method via (sieve shaker) working with vibration. After drying process, we used sieves with apertures (1.18 – 2.00) mm and sieves with apertures(600 – 300 – 212 – 150-75-63) microntable (2). The sample was put at a sieve of 2 mm. and the device was operated for 15 minutes.

Twenty two representative rock samples were collected for volumetric study and chemical analysis. Several processes were carried out for Al-Lisi samples to prepare them as abrasives and polishing items in the field of laboratories through the following:

A- Cleaning stage; it represents in cleaning the external part of the rock samples which were exposed to the weathering process and to remove dust by electrical saws.

B- breaking and grinding stage; big size rock studied samples are broken into small size items and after breaking and grinding into powders sized between less than 63 & 150 micron by electric grinding device at the central laboratories of Geological Survey and Mineral Resources Board (GSMR) Sana’a,Yemen. From the grinding outcome, the assessing tests were conducted and compared them with the results carried out on the imported samples.

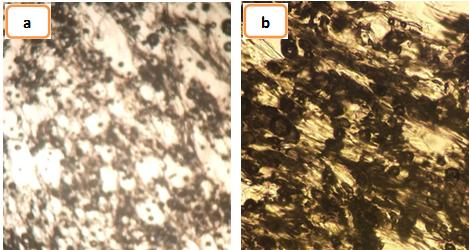

Granules shape of the imported and Al-Lisisamples from pumice powder was tested by a reflection microscope with magnification power of (40X) which is available at the laboratory of Environment and Geology, Faculty of Applied Science, Thamar University.

Petrographically, to determine the petrographic characteristics of the pumice deposits, seven representative samples were collected systematically from the well exposed rocks sequences in the pumice deposits, and thin sections were prepared following the procedure listed in Tucker (1988). The rock samples were cut perpendicular to the bedding planes to recognize all the layers of the mineralogical constituents. The petrographic sections prepared in GSMR. The polarized microscope was used to study the mineralogy of the pumice rocks using both Plane Polarized light (P.P) and Cross Nickol(C.N.).

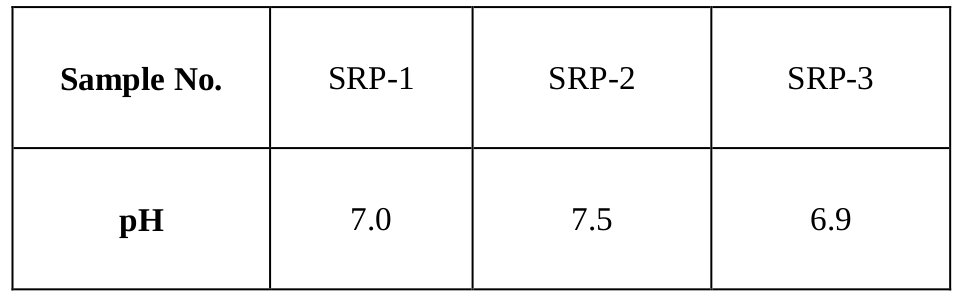

Chemically, the chemical analysis was carried out for eight selected samples of Al-Lisipumice rock and four imported pumice samples, investigating their major oxides. Major oxides were determined by X-ray fluorescence spectrometer (XRFS) techniques on a Philips PW2400 Automated Spectrometer. Also, three rocks samples were collected from Al-Lisi pumice to determine pH value table (3). The analysis were carried out at GSMR.

V. RESULTS AND DISCUSSION

A. Volumetric analysis

The volumetric rate of the imported samples concentrated on the sieve with apertures from less than 63 -150 micron as showed at the table(2). The maximum rate of powder is concentrating at the granules of 75 micron volume and represented around 91.65% followed by granules of 63 micron volume with 5.30% and then granules that less than 63 micron with 2.65% and granules of 150 micron volume that represented 0.05%, the totalvolumes represented 99.65%. Having recognized the volumetric rates the imported pumice powder, samples of Al-Lisi pumice were testing after being dried on the convection oven and passing them through sieves by (sieve shaker) and selecting avolumetric rate with the same volumetric characterizations of the imported samples.

Table 2: Particle Size Grade Of Samples

The volumetric rates of Al-Lisi pumice powder samples were concentrated on the sieves with volumes from 150 to less than 63 micron as showed in the table (2), volumes that are more than 150 micron were ignored and smaller rates were taken. The rates were 0.05% of the granules of 150 micron volume, 91.20% of the granules of 75 micron volume, 5.60% of 63 micron volume and 2.50% of less than 63 micron volume. Thus, it is found that the importantly used volumes were concentrated tremendously at the volume of 75 micron.Therefore, it is found that different materials can be produced for dental laboratories as abrasives and polishing items from AlLisi pumice rocks with the same volumetric characterization of the imported samples.

B. Test of samples shape

Comparison was conducted between granules shape of the imported and Al-Lisi samples through the general appearance of granules of imported and AlLisi pumice; it is found that, these granules are with sharp edges in different direction and glass lustering. However, their color was white similar to small glass molecules resulted by a crushing of any glass items and with very small sizes. During test, it isfound that the samples used in the study of Al-Lisi pumice powder are acute angle granules and with glass lustering resemble the shape of angle edge of the imported pumice granules which indicate that Al-Lisi granules are with good characterizations and in conformity with the imported samples in terms of general form of the granules and color; granules of the imported and Al-Lisi samples with various volumes. It is known that the characterizations of the items used as abrasives and polishing materials that they are acute angle edge, while their volume are according to the nature of usage,the bigger size of the granules, the more impact is the abrasive process and the smaller size are, the best outcomes as polishing materials (Hutching, 2002).

To create the desired outcome of the highly polished surface, the polishing process should begin with the application of the coarse grit particle. Then the process is followed by the application of a medium grit abrasive and ends with the application of a fine grit particle(Wilkins, 2009 andSawai, 2015). The shape of the abrasive particles also affects the rate of abrasion, round or spherically-shaped particles abrade slower than sharp, irregular- shaped particles (Wilkins, 2009).

C. Test of pH Samples

The result of identification of pH value of AlLisipumiceis inert table (3). The chemical inertness allows pumice to beused as abrade, it is soft enough with no damage at the surface (Wilkins, 2009,Crangle, 2011 andSawai, 2015).

Table 3: Ph Value Of Al-Lisi Pumice

1. Petrography

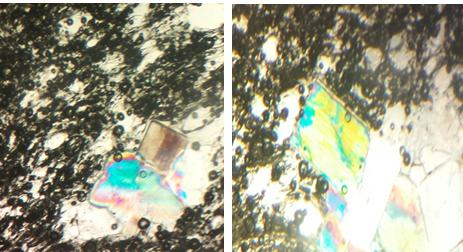

The pumice rocks are composed mainly of silica groundmass and phenocrysts.The groundmass attains about 80% of the rock volume and is composed of silica and iron oxides. The phenocrysts are Kfeldspars (sanidine, anorthoclase), plagioclase, quartz and pyroxenes.

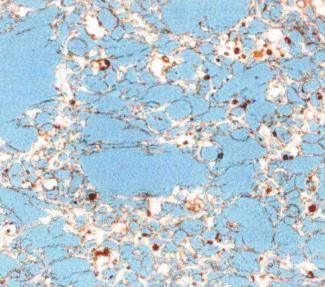

2. Groundmass

The groundmass constitutes the major component of the studied rocks. It is essentially composed of silica and minor iron oxides. The silica groundmass reveals several forms such as: (1) amorphous silica, (2) fine crystalline patches of chertand (3)scattered small crystals of quartz. The groundmass containing the vesicles consist of dark blackish volcanic glass, with dusty iron oxides. A well-developed flow – banded fabric is evident in the samples which comprise the very fine to glassy silica groundmass that composed the majority of the pumice rocks (Fig. 2 a,b) and showed little of devitrification (Fig. 2 a).

3. Iron oxides

It is present as fine grains or spots of opaque magnetite, brown to reddish brown crystals of hematite. Some hematite is of secondary origin formed as alteration product of mafic minerals (Perkins, 2002). Iron oxides range from 1 – 3%.

4. Phenocrysts

Perfect euhedral-subhedral crystals are scattered in the silica groundmass forming porphyritic texture. Several types of minerals attain phenocrysts from was recognized, these are:

5. Feldspar

Two types of feldspar minerals were recognized in thin-section slides, K-feldspar (sanidine and anorthoclase) and plagioclase (albite). The phenocrysts of feldspar are perfect euhedral and subhedral, sometimes six sided prismatic crystals (Fig.2c, d). Both types of K-feldspar were noted as well. The sandine is a characteristic minerals of acidic volcanic rocks whereas anorthoclase is a characteristic mineral of soda –rich acidic and volcanic igneous rocks (Perkins, 2002). Plagioclase is present in the studied rocks as prismaticeuhedral crystals that range in size from 0.1 – 0.3 mm. The percentage of feldspar phenocrysts range from 2 – 10%.

6. Quartz

Quartzis present in several forms and in different modal percentage, they range in size from 0.05 to 0.3 mm (Fig.2c),these are:

– quartz occurs as small, clear and euhedralsubhedral crystals present in a range 1 – 7%.

– chalcedony occurs as radiated from crystals, which range from 1 – 6%.

– cristobalite occurs as small, unhedral crystals present in a range of 1 – 3%.

– chert occurs as fine crystal aggregates that range from 1 – 5%.

7. Pyroxene

Pyroxene mineral is present in coarse and fine, perfect, euhedral and subhedral crystals(Fig.2c,d). The type of noted pyroxene mineral is a characteristic mineral ofsoda- rich igneous rocks (Perkins, 2002). The percentage of the pyroxene is less than 3% of the phenocrysts.

8. Void and vesicles

Pumice is a highly vesicular volcanic material formed by the rapid expansion of gasses during the explosive eruption of lava. The vesicles in the Al-Lisi pumice rocks constitute between 50-85% of the material mass, and appear in different shapes such as spherical, sub-spherical and sometimes irregular (Fig.2a,b). Porosity within the glass is dominated by 0.010.5 mm in diameter.

9. Textures

Several types of textures were recognized in the studied pumice rocks represented by a major groundmass and phenocryst. The type of textures are:

10. Porphyritic

It is recognized in the studied rock samples. This texture comprises crystals of feldspar, pyroxene and quartz minerals embedded in the silica-rich groundmass (Fig.2c,d).

11. Glassy texture

The glassy texture comprises the amorphous silica groundmass (Fig.2e).

12. Vesicular structure

Void and vesicles are formed by the rapid expansion of gasses during the explosive eruption of lava.

Fig 2: Microphotographs of samples from the Al-Lisi pumice rock, Yemen show: (a) a well-developed flow-banded fabric and vesicle structure, C.N. (field of view is 0.5 mm), (b) flow-banded texture, C.N. (field of view is 0.5 mm), (c) euhedralsanidine (Sa), subhedral pyroxene (Py) and subhedral quartz (Q) phenocrysts with pumice fabric, C.N. (field of view is 0.5 mm), (d) euhedral pyroxene (Py), euhedral plagioclase (Pl) and euhedralanorthoclase (An) phenocrysts in the pumice rocks, C.N. (field of view is 0.5 mm) and (e) glassy texture, C.N. (field of view is 1mm).

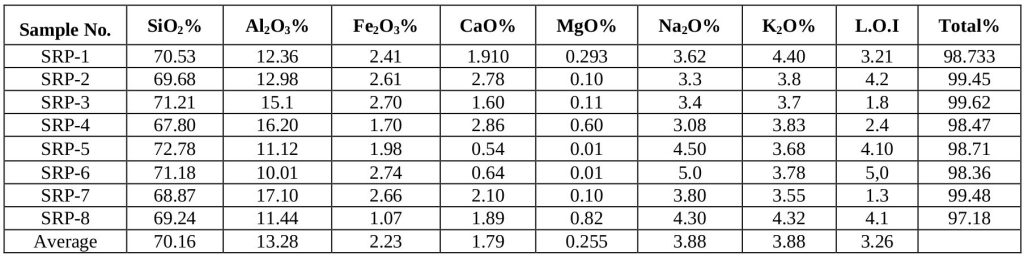

D. Chemistry

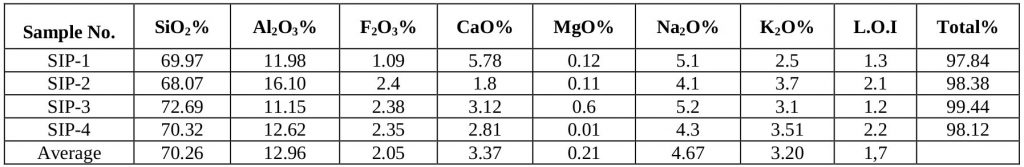

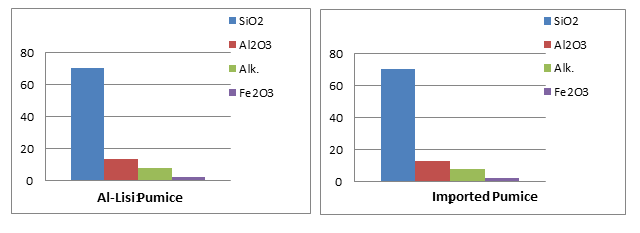

The silica in the pumice rocks of Al-Lisi is ranging from 67.80% – 72.78% with an average 70.16%, showing the similarity with silica content in the imported pumice ranges from 68.07% – 72.69% with an average 70.76%table (4, 5)(Fig.3). The aluminum oxide of the pumice rocks of Al-Lisi ranges from 10.01% -17.10% with an average 13.28%, showing the similarity with aluminium oxide content in the imported pumice ranges from11.15% – 16.10% with an average 12.96%table (4, 5) (Fig.3).

The potassium oxide in the pumice rocks of Al-Lisi locality ranges from 3.55% -4.40% with an average 3.88%, which refers to the similarity with potassium oxide content in the imported pumice ranges from 2.5%-3.7% with an average 3.7%. The results of sodium oxide percentages in the pumice rocks of Al-Lisi are ranging from 3.08% -5.0% with an average 33.87%, showing the similarity withsodium oxide content in the imported pumice ranges from 4.1% – 5.2% with an average4.67% table (4, 5) (Fig. 3).

The iron oxides in the pumice of Al-Lisi ranges from 1.07% – 2.74% with an average 2.23%, showing the similarity with iron oxide content in the importedpumiceranges from 1.09% – 2.4% with an average 2.05% table (4, 5) (Fig. 3).

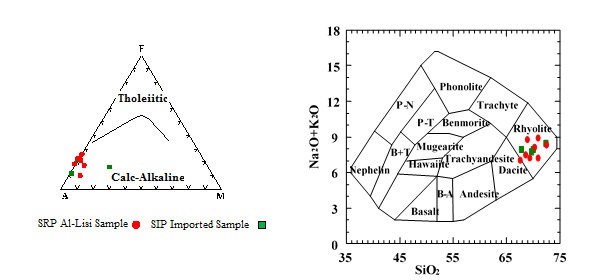

The total alkali-silica classification diagram (Fig.5) shows that the studied pumice rock of Al-Lisi area and imported pumice are acidic volcanic rhyolite.The AFM ternary diagram (Fig.4) shows that the studied pumice rock of Al-Lisi and imported pumice plot towards the A: (Na 2 O+K 2 O) apex acidic volcanics. The results of the chemical analysis of Al-Lisi pumice rocks are concludedand compared with the imported pumice rocks that refer to the similarity of Al-Lisi pumice with the imported pumice.

The silica percentages reflect that the fine silicagroundmass constitute the majority of the pumice rocks. The percentages of iron refer to the present of pyroxene minerals in the studied pumice samples. While the aluminium, sodium and potassium oxides refer to the feldspar minerals (both plagioclase and potash feldspar).The chemical composition particularly SiO 2 content is important because a high SiO 2 content will increase hardness and give the pumice its abrasive quality, the Al 2 O 3 in the structure makes the pumice highly resistant to fire and heat (Robbin, 1984).

Table 4: Chemical Analysis Data Of Al-Lisi Pumice

Table 5: Chemical Analysis Data Of Imported Pumice

| Fig 4: AFM Ternary Diagram (Irvine and Baragar, 1971) showing the composition of pumice rocks of Al-Lisi area and imported pumice. A = Na 2 O + K 2 O, F = Fe 2 O 3 and M = MgO. | Fig 5: Total alkali – silica classification diagram after IUGS (Le Bas et. al., 1986) showing the rhyolitic composition Al-Lisi pumice and imported pumice. |

VI. CONCLUSION

Volumetric study shows that there is a production possibility of Al-Lisi pumice and can be used as abrasive and polishing material in dental laboratories.The main conclusions from the petrography of Al-Lisi pumice rocks are as follows:

The pumice rocks in the area generally of a rhyolite composition with vesicles,aglassy matrix and some phenocrysts.

The silica glass of the groundmass contains few phenocrysts of feldspar, quartz andPyroxene.

The chemical analysis shows the silica content of Al-Lisi pumice ranging from67.80% to 72.78%, and the silica content in the imported pumice ranges from68.07% – 72.69% which refer to the similarities among them. The results of chemical analysis of Al- Lisi pumice samples and imported pumice are represented with identical percentages to oxides which indicate that Al-Lisi pumice rocks have approximate characterizations to the imported pumice for abrasive and polishing.

VII. RECOMMENDATIONS

The present study recommends that the electronic microscope should be used to analyze Al-Lisi pumice samples and imported pumice used in abrasive and polishing teeth, particularly electron probe- micro analysis (EPMA) should be used to know the additional materials to the imported pumice.

REFERENCES

Al-Kadasi, M., (1994). Temporal and spatial evaluation of the basal flow of the YemenVolcanic Group. Ph.D. Thesis, Royal Holloway, University of London, 301p.

Al-Sabri, A.M., (2009). Geology and economic potentiality of the scoria deposits in Thamar-Rada’a volcanic field, Yemen. Unpublished Ph.D. Thesis, Sana’a University.170 p.

Al-Sharie, H., Masoud, T., Abdulla,A .I. and Ghanem, A., (2015). Properties of lightweightcement motor containing treated pumice and limestone. Journal of Engineeringand Applied Sciences 10 (5): p 96-101. ISSN:1816- 949x.

Anusavice, K.J., Antonson, S.A., (2003). Finishing and polishing materials. In: Anusavice, K.J. editor. Phillips: Science of Dental Material. St. Louis: Elsevier Science. 2003 p.351-377.

Arce, J.I., Walker, J. and Keppie, J.D., (2015). Petrology and Geochemistry of El Chichon and Tacan: tow active, yet contrasting Mexican volcanoes.P. 25-43. Doi: 10:1007/978-3 –642 – 25890 – 9-2.

Beydoun, Z.R., As-Saruri, A.L., Mustafa, El-Nakhal, H., AlGanad, I.N., Baraba, R.S., Nani, A.S.O., Al -Aawah, M. H., (1998). International lexicon of stratigraphy V.III, Republicof Yemen. In :2nded: International Union of Geological Sciences and Ministry of Oiland Mineral Resources, Republic of Yemen, Publication 34 p.

Chiesa, S., Volpe, L.L., Lirer, L., Orsi,G., (1983). Geology of the Thamar-Rada’avolcanic field, Yemen Arab Republic, NeuesJahrbuchfuer Geologic anpalaeoctologieMonatshefte, p. 481-494.

Crangle, R.D., (2011). Pumice and Pumicite. Minerals yearbook, United States Geological Survey.p. 591-596.

Evans, E.J., Inglethorpe, S.J.D. and Wetton, P.D., (1999). Evaluation of pumice and scoria samples from east Africa as lightweight aggregates. Mineralogy and petrology,technical report. British Geological Survey. 31 p.

Founie, A., (2005). Pumice and pumicite, in Mineral Commodity Summaries. Reston, VA: USGS p.128-134.

Geitgey, R., (1994). Pumice and volcanic cinder. In D.D. Carr (Eds.), Industrial Minerals and rocks. Society for Mining, Metallurgy and Exploration, Inc. Littleton, Coloradop. 803813.

Grolier, M., Overstreet, W.C., (1978). Geology map of the Yemen Arab Republic 1:500000.U.S.G.S. Misc. Inverstig. Map, 1 – 1143-B.

Harben, P., and Kuzvart, M., (1996). Pumice and scoria. In P. Harben&Kuzvart (Eds.),Industrial Minerals, Global Geology. Industrial Minerals information Ltd. London.p.317-323.

Hutching, I.M., (2002).Abrasion process in wear and manufacturing. Proceeding of theInstitution of Mechanical Engineers. Part J : Journal of Engineering Tribology.216. p.55-62.

Irvine, T.N. and Barager, W.R.A., (1971). Aguide to the classification of commen volcanic rocks, Canadian Journal of Earth Science, V. 8: p. 523-548.

Kikkawa, N., Pender, M.J. and Orense, R.P., (2013). Comparison of the geotechnical properties of pumice sand from Japan and New Zealand. Proceedings of the 18thInternational Conference on Soil Mechanics and Geotechnical Engineering, Paris.p.239-242.

Klug, C., Cashman, K.V., Bacon, C.R., (2002). Structure and physical characteristics of pumice from climact eruption of Mount Mazama (Crater Lake), Oregon. Bull Volcanol 64: p 486-501. Doi: 10.1007/s 00445 – 002-0230-5.

Kruck, W., Schaffer, U. and Thiele, J., (1991). Geological map of the Republic of Yemen, Sheet Sana’a, Federal Republic of Germany, Federal Institute for Geosciences andNatural Resources (Ministry of Oil and Mineral Resources, Republic of Yemen), 1:250.000 Scale map. Report 156p.

Le Bas, M.J., Maitre, R.W., Streckeisen, A. and Zantin, B., (1986). A chemical classification of volcanic rocks based on the total alkalies-silica giagram. Journal of Petrology, 27: p. 745-750.

Madan, C., Bains, R., Bains, V.K., (2009). Tooth polishing : relevance in present day Periodontal practice J. Indian Sos. Periodontal, 2009, 13, p.58-59.

Manga, M., Patel, A., Dufek, J., (2011). Rounding of pumice clasts during transport: fieldmeasurements and laboratory studies. Bulletin of Volcanology, Volume 73, Issue 3,p. 321333. Doi : 10:1007/soo445-0100411-6.

Mattash, M .A., Balogh, K ., (1994). K-Ar radiometric age data on Cenozoic volcanics and their associated Tertiary intrusions from Yemen. ActaMineralogica-petrographic, Szeged-Hungary. P. 83-93.

Manetti, P., Capaldi, G., Chiesa, S., Civetta, L., Conticelli, S., Gasparon, M., La Volpe, I.,Orsi, G., (1991). Magmatism of the eastern Red Sea margin in northern part of Yemen from Oligocene to present. Tectonophysics 198. P. 181-202.

Menzies, M., Bosence, D., Al Nakhal, H. A., Al-Khirbash, S., Al-Kadasi,M. A., Al-Subbary, A., (1990). Lithospheric extension and the opening of the Red Sea: sedimentbasaltrelationships in Yemen. Terra Nova 2, p. 340-350.

Menzies, M., Al-Kadasi, M. A., Al-Khirbash, S., Al-Subbary, A.K., Baker, J., Blakey, K. R., Nichols, G., Yelland, A., (1992). Geology of Yemen in Geology and Mineral Resources of Yemen, Geological Survey and Mineral Exploration Board, Ministryof Oil and Mineral Resources of Yemen.

Pascarett-Grizon, F., Mabilleau, G. and Chappard, D., (2013). Abrasion of 6 dentifricesby vertical scanning interference microscopy. Journal of Applied Oral Science, V.21(5): p.475481. Doi: 10.1590/1679-775720130204.

Pattan, J.N., Mudholkar, A.N., Sankar, S.J., Ilangovan, D., Paula, D., (2008). Drift pumice inthe central Indian Ocean Basin: geochemical evidence. Deepsea research part 1oceanographic research.22p.

Perkins, D., (2002). Mineralogy. 2nd.Ed., Pearson Education, Inc. (Singapore), 483p.

Pichavant, M., Pompilio, M., D’Oriano,C., Di Carlo, I., (2011). Petrography, Mineralogy and geochemistry of a primitive pumice from Stromboli: Implications for the deep Feeding system. Eur. Mineral. 2011, 23. P.499-517. Doi: 10.1127/0935-1221/2011/ 0023-2109.

Presley, G.C., (2009). Pumice and pumicite and volcanic cinder. In Kogel, J.E., Trivedi, N.C.,Barker, J.M. and Krukowski, S.T. (eds). Industrial Minerals and Rocks.Commodities and Uses.7th. ed. Published by Society for Mining, Metallurgy and Exploration Inc. (SEM), Littleton, Colorado, USA. p. 743-754.

Robbins, J., (1984). Pumice-the ins and outs of a reinforced market. Industrial Minerals 200: p.31-51.

Sawai, M.A., Bhardwaj, A., Jafri, Z., Sultan, N. and Daing, A. (2015). Tooth polishing: thecurrent status. J. Indian Soc. Periodontal .V. 19 (4). P. 375-380.

Tucker, M.E., (1988). Technique in sedimentology .

Blackwell Scientific Publication: 394 p.

Wade, J.A., Plank,T., Stern, R.J., Tollstrup, D.L., Gill, J.B.,

O’leary, J.C., Eiler, J.M.,Moore, R.B., Woodhead, J.D., Trusdell, F., Fischer, T.P., Hilton, D.R.(2005). TheMay 2003 eruption of Anatahan volcano, Mariana island : Geochemical evolutionof silicic island-arc volcano. Journal of Volcanology and Geothermal Research 146(2005). P.139-170. www.Elsevier. Com /locate/ Nolgeores. Doi: 10.1016/j-j Volgeores. 2004.11.035.

Wilkins, E.M., (2009). Clinical practice of the dental hygienist. 10th .ed. Philadelphia:Lippincott Williams and Wilkins. 2009:p.727-740.

Williams, J.A., (2005). Wear and wear particles, some fundamentals.Tribiology International. 2005, 38 : 863-870.