Authors: Taha A. AL-Naaymi and Mohamed A. Ali

Taha A. AL-Naaymi: Department of Geology and Environment. Faculty of Science. Sana’a University. Yemen Mohamed A. Ali: Department of Applied Geology. Faculty of Science. AL- Anbar University. Iraq

Source: http://www.ajbasweb.com/old/ajbas/2013/September/116-124.pdf

Introduction

Scoria and Pumice have been used for centuries in the world as construction materials. They are widely spread and can be found in many places around the world where volcanic activities have been occurs. Scoria and Pumice deposits are pyroclastic rocks, which are products of explosive volcanic eruptions, they are generally produced from volcanoes having a more viscous type lava.

Scoria (S) is a vesicular glassy lava rocks of Basaltic to Andesitic composition (40 – 60 % sio2) ejected from a vent during explosive eruption, the vesicular nature of Scoria is due to the escape of volcanic gases during eruption, it is typically dark gry to black in color ,mostly due to its high iron content. It is consists of highly vesicular basic material having much higher density than Pumice (Lefond, 1983; Harben, 1995; KiliÇ et al; 2009). The glassy matrix of Scoria fragments and over several million years devitrifies to products, thus it is most economically valuable Scoria deposits are late tertiary or Quaternary in age (Mathers et al; 2000).

The vesicular structure and chemical composition of Scoria and Pumice have a series of useful properties such as, low bulk density, good thermal and caustic insulation, low chemical reactivity and very porous. This combination of attributes make Scoria and Pumice suitable for several industrial and construction application, such as an additive materials (Pozzolana) in cement industry, as a heat and sound insulating materials, as a lightweight aggregate to produce lightweight concrete and in variety of other permanent insulating applications. (Failla et al; 1997) (Gunduz, 2008), in addition to other uses such as low cost, fillers, filter materials. Also Scoria is used as a roofing granules and road metal (Harben,1995) and other architectural applications and in construction industry.Pumice was used in ancient Rome over 2000 years ago and many notable Pumice structures are still standing today (Grasser and Minke,1990).

Twentieth century witnessed rapid growth in use of light construction materials which contribute to energy saving and has increasingly been gained importance naturally. The use of lightweight construction materials such as concrete has been confined to large structures, and more in particular to structures where a high dead load to live load ratio occurs ,less reinforcing steel and lower foundation costs ,furthermore the reduced weight may to reduce the risk of earthquake forces are proportional to the mass of those response (Satish and Berntsson, 2002). Reduced dynamic actions make it easier to move the elements to be connected (Yasar et al; 2003). Economic calculation shows about five to ten percent saving due to dead load and foundation size reduction (Malekpoure et al; 2010) .From economical perspective the cost of lightweight constructions materials is somewhat more .but ultimately the total building cost is less (Mijnsbergen et al; 2000).

One of the most conventional ways to manufactur lightweight concrete is to used Scoria and Pumice as a natural lightweight aggregates, as it can be found in many places around the world where volcanoes erupt. Yemen is one of the countries that have volcanic eruptions occur during Cenozoic Era to Quaternary. The volcanic rocks in Yemen have been divided in to an older “Trap” series and a younger volcanic series (Beydoun et al ;1998).

There are numerous geological studies described volcanic fields and volcanic deposits in Yemen, but few of them described Scoria and Pumice as a construction materials. Also no studies of assessment of these deposits in manufacturing lightweight concert exsit. Schulze, 1978 reconnaissance the Pumice and pumicite deposits in Dhamar – Rada area, and GEOMIN ,1985 studed construction and industrial rocks in Y.A.R., AL – Sabri, 2003 described Scoria deposits in Yemen, occurrence, uses and investment opportunities, and in 2009 he studded geology and economic potentiality of scoria deposits in Dhamar – Rada volcanic field . However this paper aims to discusse the chemical and physical properties of Scoria and Pumice deposits in Dhamar – Rada volcanic field and the assessment of this deposits in manufacturing lightweight concert.

Geological Investigation:

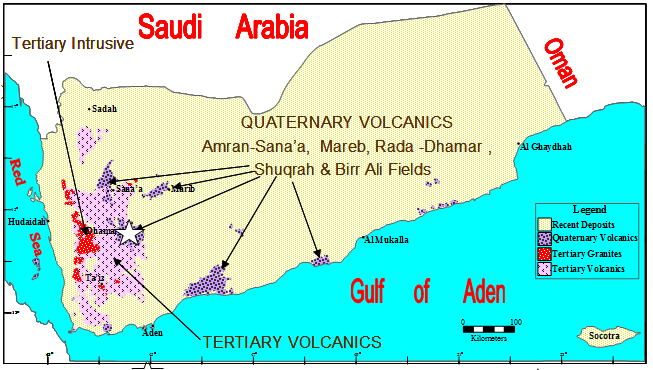

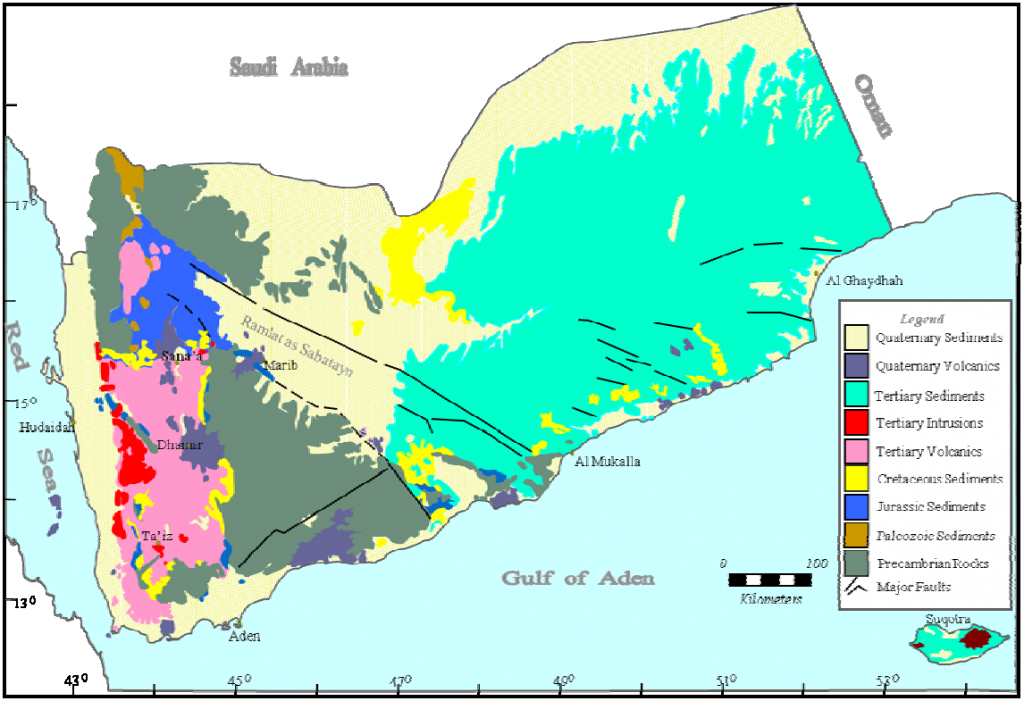

Volcanic rocks within the Arabian plate occur throughout the western Arabian peninsula over a south – to north distance of 3000 km ,from Yemen through Saudi Arabia ,Jordan and Syria (Al- Sabry 2009) together they are one of the world’s largest alkali volcanic provinces, with approximate area of 180,000 km2 (Mattash ,1994) .the Cenozoic – Quaternary volcanic rocks of Yemen previously divided in to an older “Trap” series and younger “Volcanic “ series (Beydoun, et al, 1998). The Yemen “Trap” series outcrops over a large area of western Yemen on the high plateau to the east of the Red sea with smaller northern area south of Sa`dah centered, with total area of 50,000km2 (Mattash ,1994) .The Yemen volcanic series cover a total area of about 9,000 km2 in more restricted and disconnected occurrences on high plateau above the Yemen Trap series ,in Marib graben and sporadically ,along the Gulf of Aden from Bab Al-Mandab in the west at the entrance of Red sea to Bir Ali area SW of Mukalla, and then again in the east in Qusayar – Sayhut area (AL-Sabry, 2009). The Yemen volcanic series includes two stages of volcanic activity (Late Miocene – lower Pliocene volcanism) and (Pliocene – Quaternary volcanism ).

The Pliocene – Quaternary volcanisms occur in variety places in Yemen, that cover a total area of about 9000 km2. It is divided to deferent fields (a) Sanaa –Amran, (b) Dhamar area, (c) (Marib area, (d) Shuqrah – Ahwar, (e) Balhaf –Bir Ali, (f) Qusayar – Sayhut, and inland. Also the volcanism in the Red sea ( Jabel At-Tair, Al-Zubari Island and Honaish Island (Beydoun et al; 1998). Quaternary volcanism in Yemen generated and developed through the post rift stage ,volcanic cones, domes, sheet and lava flows are the characteristic features of this volcanic series (Al-Khirbash and El-Anbaawy., 1996).

Dhamar – Rada’ volcanic field is located 95km SE sana’a city ( the capital of Yemen )extends to southeast of Dhamar city and spread to Radaa district ,it cover an area of approximately 2500 km2 (Fig. 1). This field is considered the newest volcanic field ,because of the presence of hottest area, such as Hamam Ali and rises of sulfur matereals and hot water from Al –Lisi and Asbil mountains .Structurally This field is heading to north west, parallel to the structural vectors construction of the Red sea and the East – West direction which show most of the craters volcanic eruptions. A variety of volcanic rocks occur in this field ,such as Rhyolite ,Ignimbrit, Obsidian, Bubble and Amygdaloidal basalt and various kinds of volcanic Tefra .The study area is characterized by the presence of Scoria Cinder, cones and explosive craters, many of the cones have horseshoe shaped morphologies reflecting either the predominant wind direction during cone building, or explosive removal of the side of the cones by directed volcanic blast (Chiesa et al;1983 ).

The moust of pumice deposits in Dhamar – Rada’ volcanic field present within acidic Quaternary volcanic series in Al – Lisi volcano, as it is located east of Dhamar city, of about 7 km, and Isbil volcano located about 31 km east of Dhamar city (Fig.1).The Pumice and Pumicite layers are located in the area around AL-Lisi volcano which cover about 15 km2 .These pyroclastic layers are generally flat or inclined up to 10° in various directions (AL-Sabry, 2009). The upper part of the section contains a pyroclastic Pumice flow and thin Pumice fall layers. In the surge deposits planar and sand wave bed –forms are presented (Chiesa et al ;1983). The Isbil volcano is the most prominent strato – volcano in the Dhamar – Rada’ volcanic field . The Pumice flow deposits occur during the latest stages of the volcanic activity. However a thick succession of Pumice – fall, surge and pyroclastic pumice – flow deposits is exposed in the upper part of the caldera wall (AL-Sabry, 2009).

Geological map of Yemen (After YGSMRB, 2004)

Methodology:

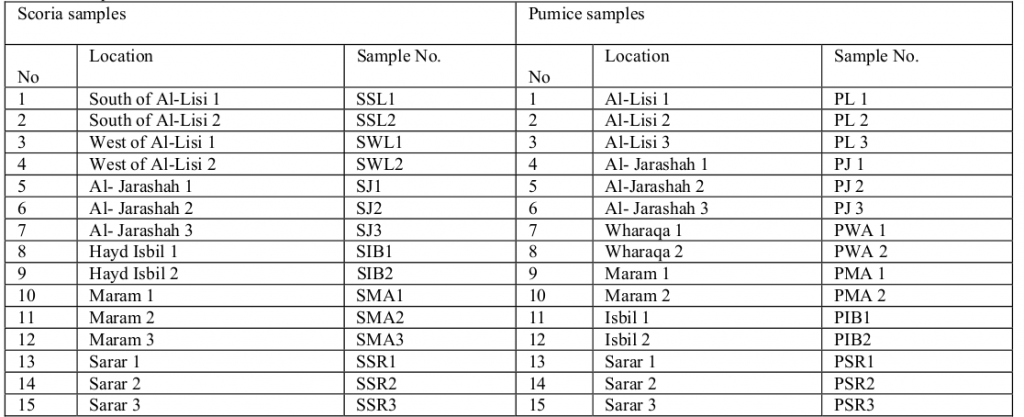

Thirty representative samples were collected from different areas of Dhamar – Rada’ volcanic field. These samples were 15 samples for Scoria deposits and 15 samples for Pumice deposits, Table(1). Scoria samples were collected from fall–out and the local grain –avalanches down on a cones .The Pumice samples were collected from Pumice–flow deposits and pumice fall layers. The adequate quantity of each sample was collected, labeled, and the location was pointed. The samples were cleaned and prepared for analyses. The chemical analyses of the Scoria and Pumice samples were achieved using X-Ray Florescence (XRF) technique for major oxides and traditional wet –chemical analyses for loss on ignition (LoI) and the physical properties of these samples such as grain size distribution, bulk density, water absorption and porosity were tested. A thin section was prepared in the central laboratories of the Geological Survey and Mineral Resources Board in Yemen, the polarized microscope was used to study the porosity of the Scoria and Pumice using cross polarized light (C.P.). In this study ,scoria and pumice were used as both coarse and fine aggregates for assessment in the manufacturing of lightweight concrete. Other measurements were carried out in the laboratory of Faculty of Engineering in Dhamar University.

Table 1: Samples localities and Serial Numbers .

Result and Discussion

Chemical analysis:

Chemical analysis:

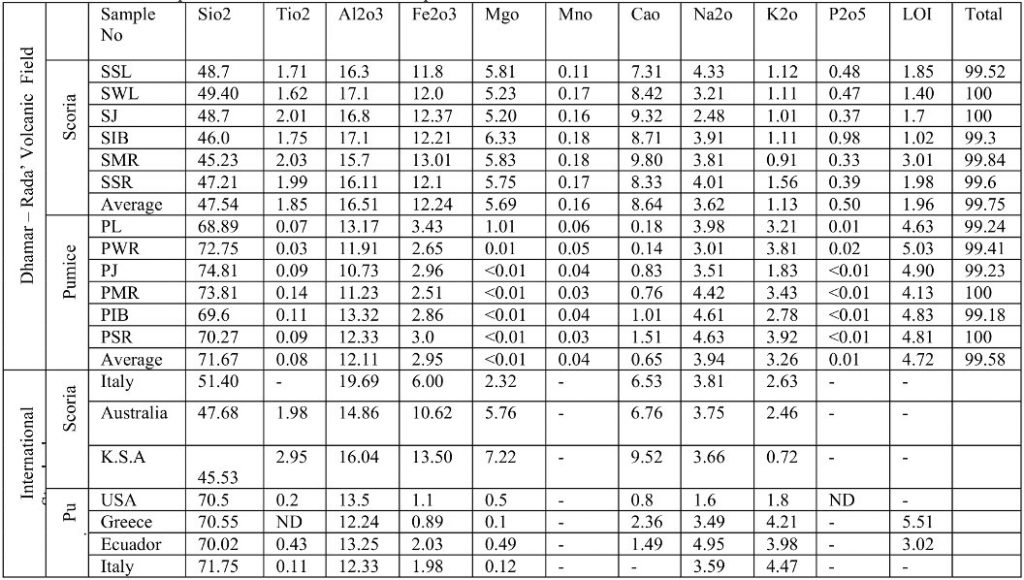

The results of chemical analysis for major oxides and traditional wet – chemical analyses for loss on ignition (LOI) are given in table(2) .Twelve representative samples for Dhamar – Rada Scoria and Pumice deposits was analyzed in Amran cement factory. The comparison of chemical data for commercial Scoria and Pumice are also listed . The chemical composition ,particularly Sio2 content, is important because a high Sio2 content will increase hardness and resistance to chemical attack (Robbins,1984).

It is clear that the percentage of the major element compositions of Scoria and Pumice deposits in Dhamar – Rada’ volcanic field are broadly comparable to those of the world’s similar deposits, although their Iron oxid (Fe2o3) wt% contents in Dhamar – Rada’ Scoria deposit are markedly higher .The average percentage of (Mgo)wt% and (Cao)wt% contents in Pumice deposits are (<0.01) and (0.65) wt%. They are lower percentages comparatively with that of Pumice in the international standard. In generally it is clear that the average percentages of chemical analyses of the Scoria and Pumice deposits of Dhamar – Rada volcanic field are within the range of the chemical analyses of the world’s similar deposits.

Table 2: Chemical Composition of Scoria and Pumice Deposits in Dhamar – Rada’ Volcanic Field .

Physical properties:

Grain size analysis:

Grading of the fine and coarse aggregate and its proportions used have an important effect on the concrete, as a well graded aggregate will have a continuous distribution of particle sizes ,producing a minimum void content and will require a minimum amount of cement paste to fill the voids (ACI 211 .2 – 98).

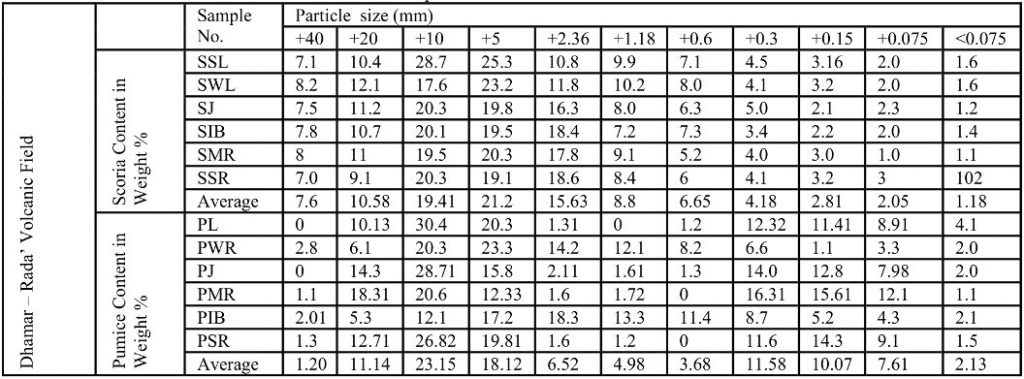

The Scoria and Pumice deposits from Dhamar – Rada’ volcanic field were sieved (dry sieving) using standard sieves, with the following sizes ; > 40mm, 20mm, 10mm, 5mm, 2.36mm, 1.18mm, o.3mm, 0.15mm, 0.075mm, <o.o75mm .Then weight the size fractions retained on each sieve .The results are shown in Table (3) and represented graphically in Fig.(3). It is clear that the Scoria deposits of all areas investigated from Dhamar – Rada’ volcanic field are approximately of the same granulometric composition and indicate that these deposits are well graded .The pumice deposits are different granulometric composition in areas investigated from Dhamar – Rada volcanic field and indicate that these deposits are poor to well graded.

According to the results, the fractions between 20mm and +2.36mm would amount to approximately

66.82% to the scoria deposits and the amount between +1.18mm to +o.075mm is approximately 25.67% and 1.1% in the fraction less than<0.075mm. The grain size distribution of Scoria deposits from Dhamar – Rada’ volcanic field meets international standards for lightweight concrete, despite of its natural condition of the aggregates (scoria and pumice) as it does not have the right particle to produce concrete and it must be processed before using it in a mix. <0.075mm. The Pumice deposits of Wharaqa and Isbil areas have the fractions between +20mm to +2.36mm and would amount to approximately 58.4% the amount fraction between +1.18mm to +0.075mm approximately 37.1 % and 2.01 % in the fraction less than <0.075mm. In the Al-Lisi ,Jarashah ,Maram and Sarar areas the fractions between +20mm to +2.36mm would amount to approximately 59.20 % and the amount between +0.3mm to +0.075mm approximately 36.6 % and 2.17% in the fraction less than.

Table 3: Grain Size Distribution of Pumice and Scoria Deposits in Dahmar – Rada’ Volcanic Field.

Pumice(B) Deposits.

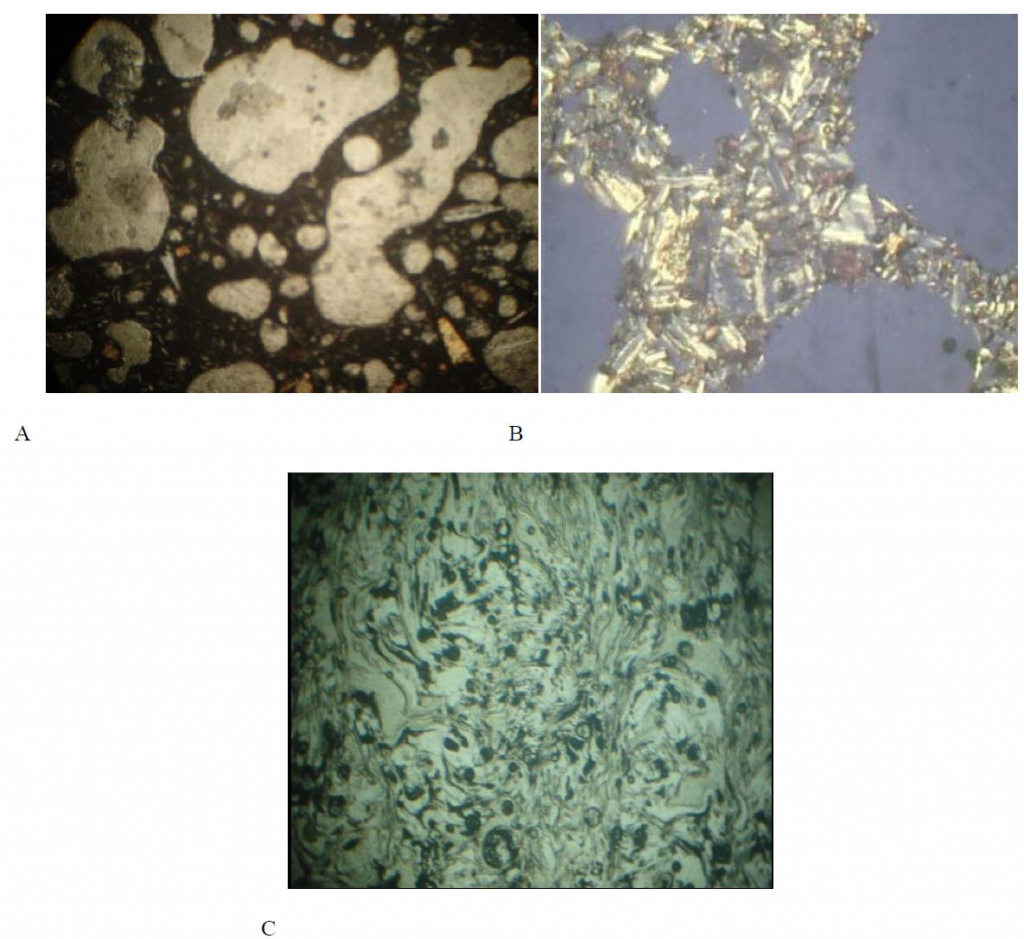

Porosity:

Pores are defined as the air space inside individual aggregate (ACI 213 R – 03). Scoria and Pumice are highly vesicular volcanic material formed by the rapid expansion of gasses during eruption of lava. The porosity of Scoria and Pumice deposits of Dhamar – Rada’ volcanic field was tested according to British standard (BS).The calculated values of porosity range between 47.3 to 56.3% for scoria with an average of 51.66%, and the porosity range between 57.3 to 66.1 % for pumice with an average of 60.65% Table(4).

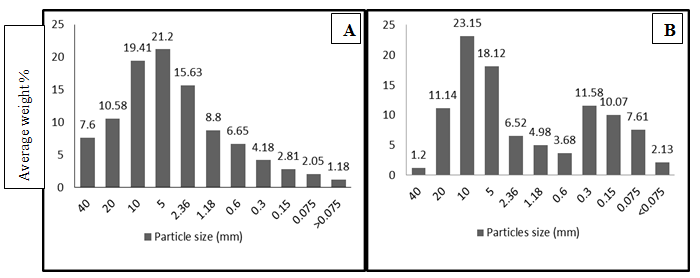

In thin sections under polarized microscope ,most of the pores in scoria samples are interconnected Fig.(4,A). It is clear that the pores in scoria deposits are larger than pores in Pumice and appear with different shapes and the voids walls in scoria samples are thicker than in Pumice Fig. (4,B).The vesicles in Pumice samples are densely packed with very thin pore walls. A discrepancy between porosity measured in thin section on one hand and that measured in laboratory is thus expected (Franzson el al; 2001). In some altered scoria the vesicles are totally or partially filled with secondary minerals such as Carbonate, Quartz and possibly Zeolites (Al – sabriy 2009).

Water absorption :

Water absorption of Scoria and Pumice deposits was tested according to British standard (BS 812). The water absorption of Scoria deposits ranged between 28% to 33% with an average of 30.7 % and the absorption of Pumice deposits ranged between 29.2 % to 37% with an average of 31.6% table(4). According to (FIP 1983) the water absorption of lightweight aggregate is up to 30% .Neville and Brooks, 1987 clarify that the increas of water absorption of the aggregate has a decreasing effect on the workability of the mix. The water absorption gives an indication on both porosity percentage and the degree of the connectivity between pores (Evans, et al;1999). According to the results, it is clear that the increase in water absorption is related to the increase of the porosity in each of the study samples.

Bulk density:

Bulk density of the Scoria and Pumice deposits for the Dhamar – Rada’ volcanic field was carried out accordance with British standards (BS. 812). Its values were reported for combined fine and coarse aggregate in Table (4). The bulk density of Scoria deposits ranged between 1010 kg / m3 to 841kg / m3 with an average of 907 kg / m3, and the bulk density of Pumice deposits ranged between 811 kg/ m3 to 701 kg / m3 with an average of 743 kg / m3 . According to the results, the bulk density of Scoria samples are greater than that of the Pumice samples, It is essentially controlled by a combination of three variables; porosity, particle size and density of the volcanic glass (Evans ;et al 1999). However the bulk density of Scoria and Pumice deposits meet the bulk density requirement for combined fine and coarse aggregate for concrete specified by (ASTM).

Table 4: The Porosity , Water Absorption , Bulk Density , of Scoria and Pumice from Dhamar –Rada’ Volcanic Field.

Investigation on Scoria and Pumice Deposits in Lightweight Concrete:

Concrete Mixture Composition And Sample Preparation:

The Scoria and Pumice deposits in the Dhamar- Rada’ volcanic field were used as an aggregate in the production of lightweight concrete. The Scoria and Pumice aggregate were separated in two sizes for the concrete mixes preparation of +20mm to +5mm as coarse aggregate and +2.36mm to 0 as fine aggregate.

The concrete mixtures were prepared by using Scoria and Pumice aggregate. A Scoria lightweight concrete (SLWC) mixture was made using only Scoria as an aggregate (443 g coarse aggregate and 366g fine aggregate) ,further more a Pumice lightweight concrete (PLWC) mixture was made using only Pumice as aggregate (470 g coarse aggregate and 347g fine aggregate). The combination of water to cement ratio (W/ C) was (0.5) which maintained a constant workability.

The aggregate were washed ,and then made saturated surface dry by immersing under water for 24 hours before casting of concrete .The Portland cement used in the investigation was supplied from Amran cement factory and fresh water used to mixture preparation. The test specimen were 100mm cubes as per BS 1881 – part 116 for compressive strength .All specimens were compacted by external vibration ,the specimens were removed from the moulds after 24 hours of casting and cured under water at a temperature of 23 ± 2 C° until testing at 28 days .Six cubes for compressive strength were tested at an age of 28 days and other six cubes for bulk density were tested at same time.

Results and Discussion on Compressive Strength and Bulk Density:

Compressive Strength:

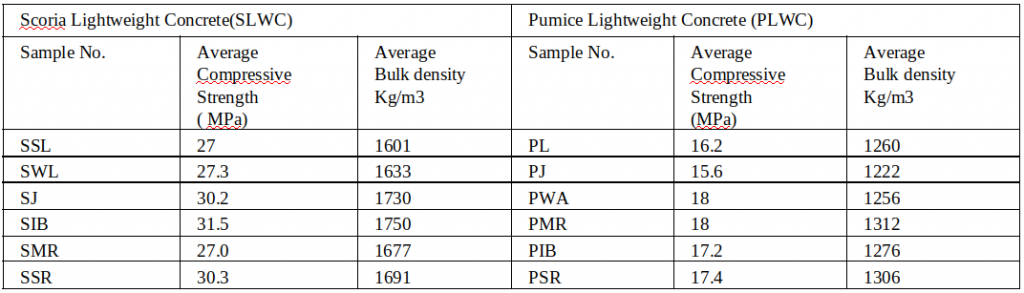

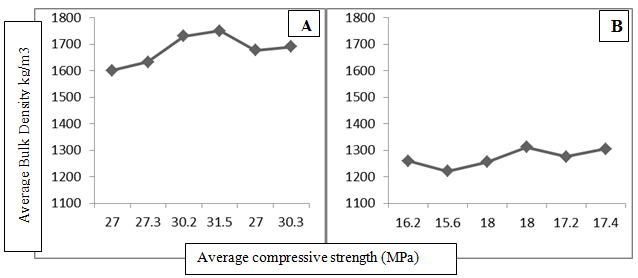

The cubes compressive strength of concrete was tested after 28 days and are presented in Table (5). The compressive strength of Scoria lightweight concrete (SLWC) are varies between 27 to 31 Mpa, the 28 days compressive strength of Pumice lightweight concrete (PLWC) varies between 20 to 15.6 Mpa. The lightweight concrete made with 100% fine and coarse scoria aggregate satisfy the minimum requirement of (ASTM C-330) structural concrete .Therefore, these lightweight concrete can be used in deferent Civil engineering field. It is observed from the results in Table (5)and Fig.(5) that the compressive strength of concrete depends on the unit weight of concrete ,the lower of the unit weight of concrete the lower limit of the concrete strength .The increase of porosity (decreased limit bulk density) of lightweight aggregate reduces the unit weight, and also reduce the strength of concrete.

Dry unit weight (Bulk density):

Average dry unit weight were given in Table (5).The dry unit weight of the Scoria lightweight concrete (SLWC) ranges between 1750 to 1601 Kg / m3, and the dry unit weight of the Pumice lightweight concrete (PLWC) are between 1312 to 1222 Kg / m3 which were both lower than the (SLWC).

Therefore, according to ASTM330 these concretes can be classified as a lightweight concrete (LWC) in terms of unit weight requirements .It can also be observed from Table (5) that the dry unit weight of the (PLWC) are less comparative to the dry unit weight to (SLWC). This is direct results of the bulk density of the Pumice aggregate which was lighter than the Scoria aggregates.

Table 5: Average Compressive Strength After 28 Days and Bulk Density of Lightweight Concrete.

Conclusions:

1- The chemical analyses results revealed that Scoria deposits in the Dhamar – Rada’ volcanic field have Basaltic composition with an average of 47.54% Sio2 , 16.5 %Al2o3 ,12.24 % Fe2o3 ,5.69% Mgo ,8.64 % Cao ,3.62 %Na2o and 1.96 LOI and pumice deposits in the same field have Rhyolitic composition with an average of 71.67% Sio2, 12.11 % Al2O3, 2.95% Fe2O3, <0.01%Mgo,0.65%Cao ,3.94 %Na2o , 3.26 %K2o and 4.72 % LOI. The chemical analyses of the Scoria and Pumice deposits of Dhamar – Rada’ volcanic field are within the range of the chemical analyses of the international standard of similar deposits.

2- The grain size analyses showed that the recovery of the fraction to the Scoria between +20 mm and +1.18 mm would amount to 75.62 % and 1.18 % in the fraction <0.075 mm, the recovery of the fraction to the Pumice between +20mm and +1.18mm would amount to 63.91 % and between +0.3mm and +0.075 mm would amount to 29.26 % and 2.13 in the fraction <0.075mm.

3- The physical properties showed that the average of porosity, water absorption and bulk density to the Scoria deposits are 51.66% , 30.17 % and 907 Kg/cm3 and the average of porosity ,water absorption and bulk density to the Pumice deposits are 60.56% ,31.6% and 743.8 Kg/cm3. It is clear that the Pumice deposits is lighter than the Scoria deposits according to the results

4- The compressive strength of lightweight concrete cubes after 28 days varies between 27 and 31.5 Mpa with density between 1601 and 1750 Kg/m3 for the Scoria lightweight concrete (SLWC). The Pumice lightweight concrete (PLWC) cubes after 28 days varies between 15.6 and 17.4 Mpa with density between 1222 and 1312 Kg/m3.

5- The chemical and physical properties of the Scoria and Pumice deposits in the Dhamar – Rada’ volcanic field show that these are generally suitable as a light weight aggregate and, satisfying of the ASTM requirements for product lightweight concrete.

References

ACI committee 211,2004. ”standared practice for selecting proportions for structural lightweight concrete, ACI211. 2-98, manual of concrete practice ,American concrete institute. Detroit, Reapproved.

ACI committee 213, 1987. “Guide For structural lightweight Aggregate Concrete, ACI 213R-o3, Manual Of Concrete Practice, American Concrete Institute, Detroit.

AL – Sabri, A.M., 2003. Scoria Deposits In Yemen :Occurrence, Uses and Investment Opportunities .Eighth Arab Conference For Minerals Resources. Sana’a, pp: 91-120.

AL-Sabri, A.M., 2009. Geology And Economic Potentiality Of The Scoria Deposits In Dhamar – Rada Volcanic Field, Yemen. PHD. Thesis Sana’a University, Faculty Of Science, Dep. Of Earth and Environmental Science.

AL –Khirbash, S.A., and M.I. EL-Anbaawy, 1996. Geology Of Yemen. Obadi studies and publishing center Sana’a ,Yemen, 206PP.

American Society for testing and materials; ASTM C330, Standard Specification For Lightweight Aggregates For Structural Concrete.

Beydoun, Z.R., M.A. As – Saruri, H. EL – Nakhal, T.N. AL – Ganad, R.S. Baraba, A.O. Nani and AL – M.H. Aawah, 1998. International Lexicon Of Stratigraphy, Republic Of Yemen, IUGS and Ministry Of Oil and Mineral Resources, Sana’a, Republic of Yemen, pp: 245.

B.S., 1995. Testing aggregate part 2 :Methods Of Determination Of Density. B S 812-2: 1995.

Chiesa, S., L. Lavolpe, L. Lirer and G. Orsi, 1983. Geology of The Dhamar – Rada Volcanic Field, Yemen Arab Republic. N. Jb. Geol. Pal ant pp: 481-494.

Evans, E.J., S.J.D. Inglethorpe and P.D. Wetton, 1999. Evaluation Of Pumice And Scoria Samples From East Africa as Lightweight Aggregates. Mineralogy and petrology technical report, British Geological Survey, Key worth, Nottingham, NG125GE.UK.

Failla, A., P. Mancuso, N. Miraglia, V. Ruisi, 1997. Experimental Theoretical Study on Pumice Aggregate Lightweight Concrete. Technical Report. The instuto di Scienza delfe construrioni, Facolta eli ingegneria, Palermo, published by minister o delta publica, Italy.

FIP., 1983. FIP manual of lightweight aggregate concrete 2nd ed. London, Surrey university.Press.

Franzson, H., S.P. Gualaugsson and G.O. Frialeifsson, 2001. Petrophysical Properties Of Icelandic Rocks. Proceedings of the 6th Nordic symposium an petrophysics 15 – 16 may 2001, Trondheim, Norway.

GEOMIN, 1985. Report on the inventory of the Construction and Industrial Rocks in Yemen Arab Republic. GEOMIN/YOMINCO, Contract No. 1118/1983, Bucharest, pp: 161.

Grasser, K., and G. Minke, 1990. Building With Pumice, Deutsche Gesellschaftfur Technische Zusammenarbeit(GTZ) Gmb H. Eschburn Germany.

Gunduz, l., 2008. The Effects of Pumice Aggregate/ cement ratios on the low – strength concrete properties construction. Building materials, pp: 721-728.

Harben, P.W., 1995.The Industrial Minerals ,hand book (2nd ed.). Aguide to market, specification and prices. Metal bulletin pls, London, pp: 253.

Harben, p. and M. Kuzvart, 1996. Pumice and Scoria. INP. Harben and M. Kuzvart (Eds.),Industrial minerals, Global Geology (pp. 317 – 323). Industrial minerals information Ltd. London.

Lefond, S.J., 1983. Industrial Minerals and Rocks. Society of Mining Engineers. American Institute of Mining , Metallurgical and Petroleum Engineers, Inc. New York., 2: 723-1446.

KiliÇ, A., C.D. Atiş, A. Teymen, O. Karahan and Kamuran Ari, 2009. The Effects Of Scoria and Pumice Aggregates On The Strengths and Unit Weight of Lightweight Concrete, Scientific Research and Essay, 4(10):

961-965.

Malekpour, S., A. Mohammadjafari, S. Nazari and S.P. Seyyedi, 2010. Producing Lightweight Concrete Using Pumice and Mineral Aggregates and Comparing the Curing Process of Autoclave With Saturated Condition. Journal of Applied Sciences, 10(11): 966-1000.

Mathers, S.J., D.J. Harrison, C.J. Mitchell and E.J. Evans, 2000, Exploration ,Evaluation and Testing Of Volcanic Raw Materials for Use in Construction, British Geological Survey, pp: 116.

Mattash, M., 1994. Study of The Cenozoic Volcanic and Their Associated Intrusive Rocks In Yemen Relation to Rift Development Ph. D. thesis Budapest, pp: 112.

Mijnsbergen, J.P.G., G. Bosmans and R. Vanselst, 2000. Definitions and international consensus report, brite euram project BE96 – 3942 eurolight con, report BE96 – 3942 – RI.

Neville, A.M. and J.J. Brooks, 1987. Concrete Technology. Printice – Hall, New Jersey, USA.

Robbins, J., 1984. Pumice the ins and outs of arein forced market. Industrial Minerals., pp: 31-51.

Satish, C., and B. Leif, 2002. Lightweight Aggegate Concrete, Noyes Publications, New York, USA.

Schulze, K.H., 1978. Pumice and Pumicite Reconnaissance in the Dhamar – Rada Area. Yemen Arab

Republic :German advisory Group, Yemen Minerals and Petroleum Authority, technical Report. Hannover, pp: 13.

Yasar, E., C.D. Atiş, A. KiliÇ and H. Gulsen, 2003. Strength Properties of Lightweight Concrete Made With Basaltic Pumice and Fly ash . Mater. Lett., 57: 2267-2270. YGSMRB, 2005. Annual Technical Report, Sanaa, Yemen.